Revolutionizing manufacturing operations: Top 5 tools for efficiency and visibility

While digital transformation promises better efficiency on the factory floor, many companies struggle to connect their tools, teams and timelines. Find out how manufacturers can overcome common roadblocks—from disconnected departments to planning blind spots—and build a clear path towards production excellence.

Table of contents

How digital transformation drives production excellence

The digital transformation challenge in manufacturing

The missing link in manufacturing excellence

Transforming manufacturing performance with Easy Redmine

1. Cross-departmental task management eliminates production bottlenecks

2. Clarity in production planning with WBS

3. Resource management for optimized production capacity

4. Integrated quality management with traceability

5. Connected documentation and SOP tracking

Boost performance in manufacturing operations

How digital transformation drives production excellence

In today's competitive landscape, performing manufacturing operations efficiently is no longer optional—it's essential for survival. As industrial automation continues to reshape factory floors worldwide, manufacturers face mounting pressure to streamline everything from prototype manufacturing to full-scale production.

The digital transformation challenge in manufacturing

The manufacturing sector stands at a critical crossroads. While advanced equipment and automation solutions promise unprecedented efficiency, many companies struggle with the human side of the equation:

- coordinating teams,

- tracking projects,

- maintaining visibility across departments.

According to McKinsey research, digital transformations in manufacturing frequently fail not because of technology limitations, but because solutions are deployed without clear links to business needs. The result?

Valuable manufacturing data goes unused, production issues take too long to diagnose, and executives lack real-time metrics for strategic decision-making.

The missing link in manufacturing excellence

What if you could seamlessly connect your shop floor operations with your strategic planning? What if every department—from R&D to quality control—could work from the same playbook, with complete visibility into tasks, deadlines, and dependencies?

This is where Easy Redmine enters the picture, serving as the vital connective tissue between your existing manufacturing systems and the people who make your operation run.

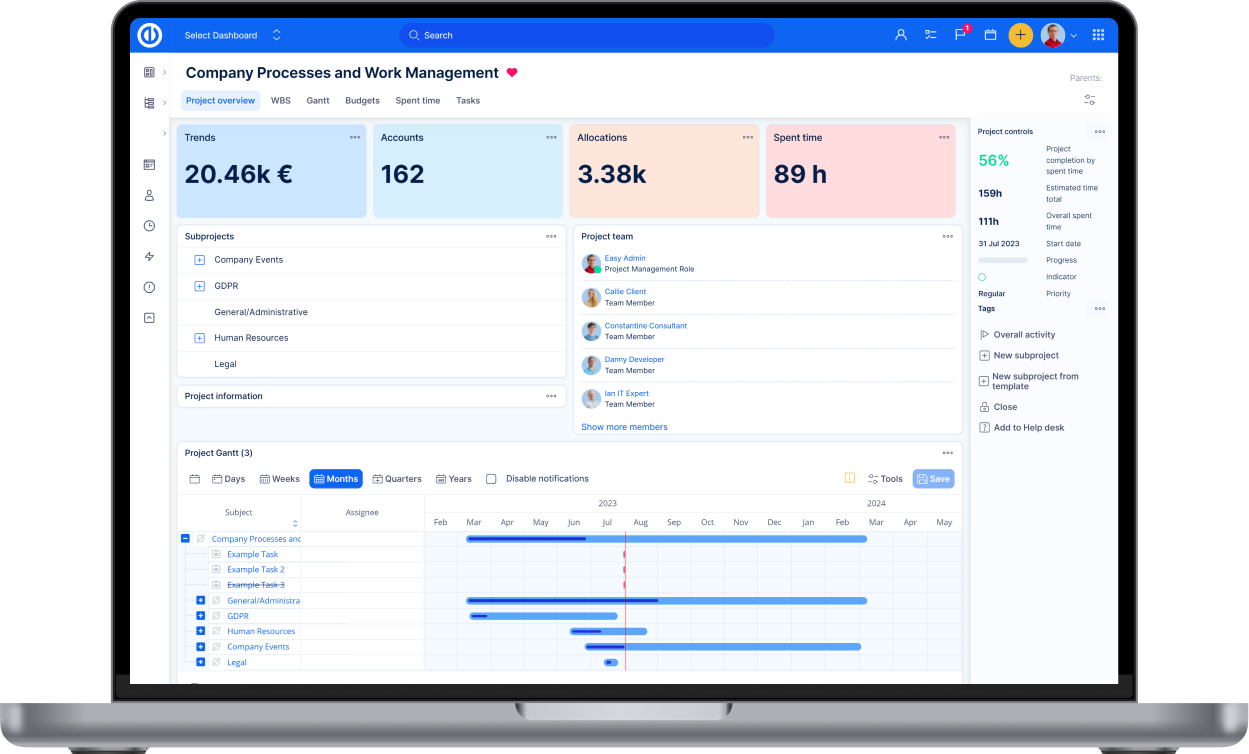

Task management with Gantt charts in Easy Redmine

Transforming manufacturing performance with Easy Redmine

Discover five specific ways Easy Redmine helps achieve manufacturing excellence:

1. Cross-departmental task management eliminates production bottlenecks

In manufacturing environments, task fragmentation across departments is the number one killer of deadlines.

To picture this, imagine that facility engineering designs and builds JIGs (tools or fixtures). Once the JIGs are ready, product engineering reviews and updates the Standard Operating Procedures (SOPs) to reflect any changes in tools, methods, or workflow. With updated SOPs and JIGs ready, manufacturing begins the final setup for actual production, ensuring everything is aligned and ready for execution.

In this scenarion, Easy Redmine is used as task tracking tool to:

- Track tasks across departments

- Ensure sequential progress (JIGs → SOPs → Setup)

- Provide visibility and accountability

- Highlight delays or blockers

This shared visibility eliminates waiting games and bridges communication gaps that typically plague manufacturing operations. Easy Redmine supports this with task management features that ensure every department knows exactly what needs to be done, by whom, and by when.

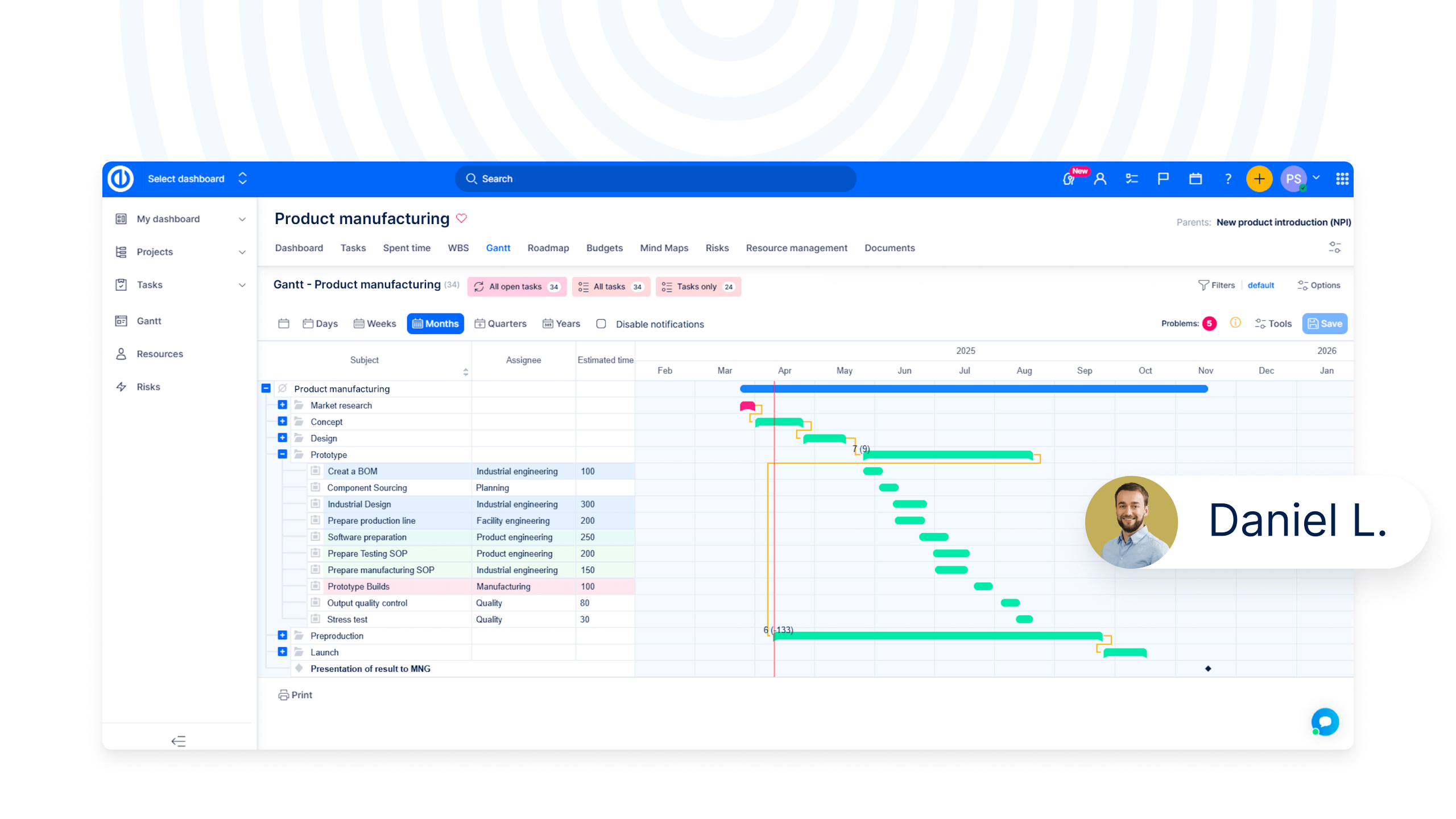

2. Clarity in production planning with WBS

Manufacturers must orchestrate countless activities before the first unit rolls off the line. When launching a new model, you'll need coordinated inputs from industrial engineering, QA, and facility teams. WBS ensures no critical step falls through the cracks, keeping your manufacturing technologies and processes perfectly aligned.

Easy Redmine's WBS transforms this complexity into clarity by visualizing all preparation work, breaking down the big picture into manageable steps, and assigning those steps to appropriate teams with clear deadlines.

WBS for work management

Consider AYESA's struggle before their transformation: They used multiple disconnected tools (SAP BPC, MS Project, Jira, and Excel), making it nearly impossible to get a clear view of project status. This fragmentation created blind spots, delayed decision-making, and hindered their ability to respond to market changes.

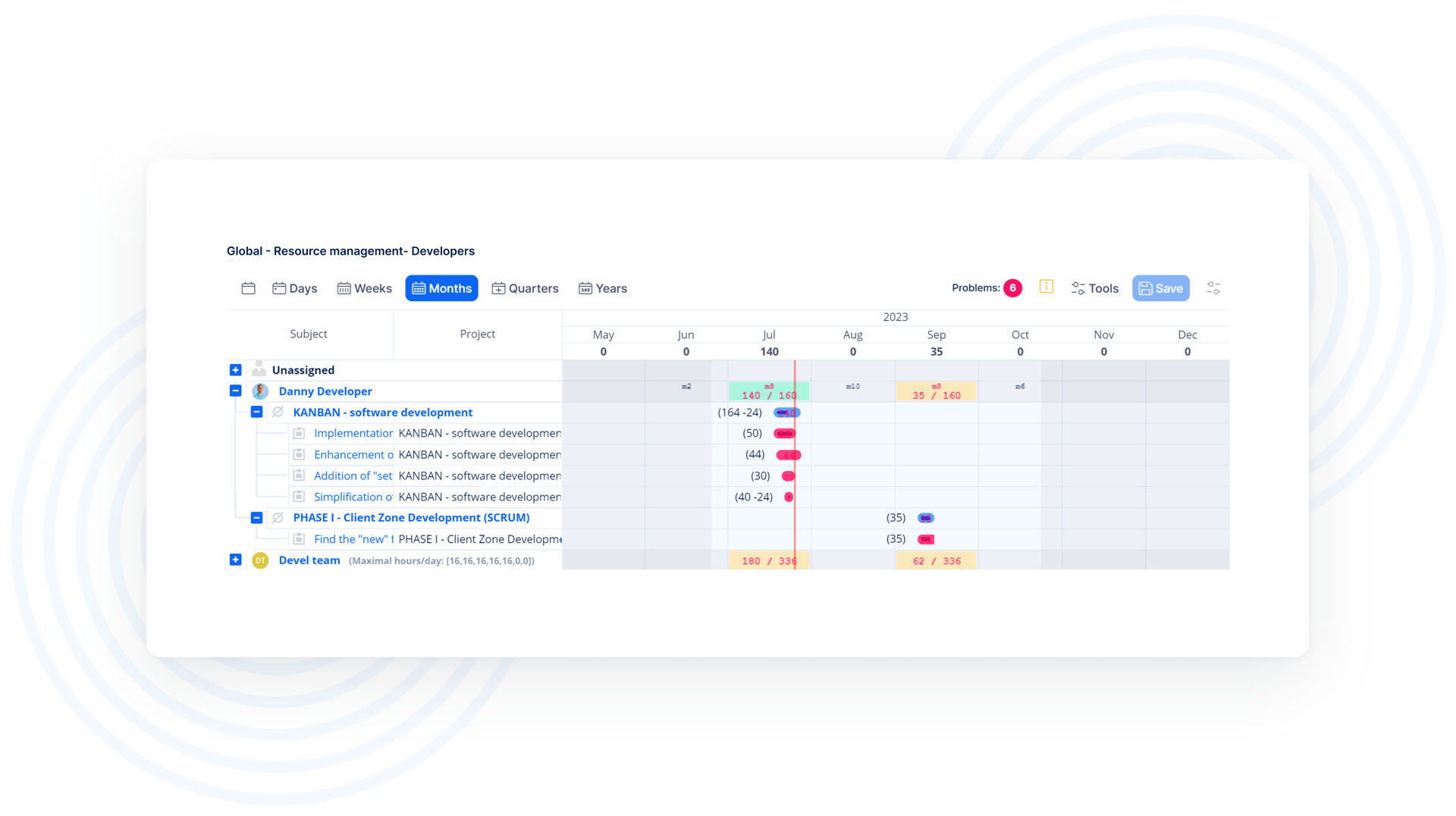

3. Resource management for optimized production capacity

Balancing human resources across multiple production lines or projects is a constant challenge in manufacturing operations.

As planning teams adjust shifts and manufacturing teams prepare for production ramp-up, everyone gains visibility into updated workloads, allowing potential bottlenecks to be resolved before they impact production.

Easy Redmine's visual resource management tools allow production managers to allocate the right people to the right jobs at the right time—preventing both team overload and idle resources.

Resource management in Easy Redmine

4. Integrated quality management with traceability

Quality control is non-negotiable in modern manufacturing services. If output quality control finds a failed test, it’s easy to trace back tasks to see where it went wrong—whether it’s from material, engineering, or process setup.

Whether conducting material input checks, in-line product testing, or final quality benchmarks, Easy Redmine tracks all quality-related tasks in one centralized location.

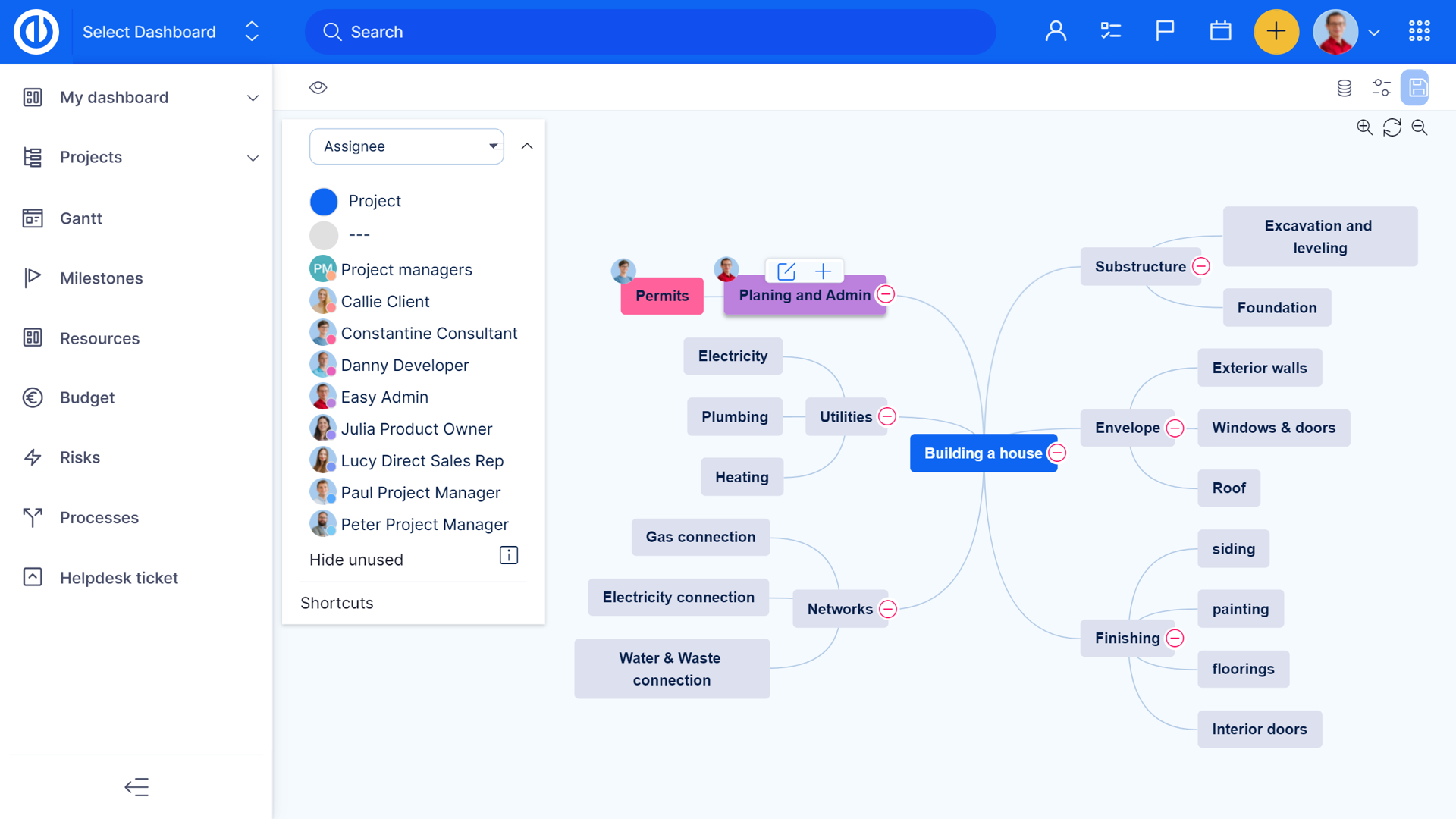

5. Connected documentation and SOP tracking

Standard Operating Procedures (SOPs), bills of materials aka BOMs, and technical documentation are everywhere—and often stuck in emails or spreadsheets.

You probably already know that the ISO 9001 international quality standard requires identifying all manufacturing processes that may impact product quality and documenting them as standard operating procedures.

Easy Redmine connects documents directly to tasks, departments, or product components—ensuring everything remains findable, versioned, and up-to-date.

Customised dashboards in Easy Redmine

Boost performance in manufacturing operations

The most successful companies are those implementing cutting-edge manufacturing technologies and comprehensive manufacturing services that connect every aspect of their operation.

Easy Redmine helps manufacturers achieve this by improving cross-department coordination, providing clear production planning with WBS, balancing team workloads through Resource Management, and maintaining full traceability of tasks. With all documentation and SOPs connected to live projects, every team works from a single source of truth.

Try Easy Redmine for project and work management to see how it can help you transform and leverage your production performance!