Effective project management in medical manufacturing: Overcoming key challenges

Medical device manufacturing is a highly regulated and complex industry, where precision, compliance, and efficiency are non-negotiable. However, this industry often faces a myriad of challenges related to project management.

Fortunately, leveraging the right project management tools can help streamline operations, reduce costs, and ensure compliance while improving overall productivity. Explore some of the key challenges and how modern project management solutions can mitigate these hurdles.

Table of contents

Regulatory compliance challenges

Quality control and risk management

Resource allocation and efficiency

Supply chain disruptions

Cost management

Team collaboration and communication

Technological integration

How to achieve success in medical device manufacturing

Regulatory compliance challenges

The medical device industry is subject to stringent and evolving regulatory requirements. Manufacturers must continuously stay on top of updates to ensure compliance and avoid costly penalties and regularly monitor updates from agencies like the FDA and EMA. Manufacturers exporting to the international medical device market must also ensure compliance with country-specific standards, such as BfArM in Germany, AEMPS in Spain, and ANSM in France.

Without a reliable system in place, it’s easy to miss critical deadlines or fail to maintain proper documentation.

How project management tools help

- Track regulatory updates and deadlines: Automated alerts can notify teams when regulations change or deadlines approach, reducing the risk of non-compliance.

- Ensure compliance documentation is up-to-date: Tools can store, organize, and automatically update compliance-related documents, reducing manual work and human error.

- Streamline the audit process: Having all compliance data stored in one platform makes audits simpler and faster, ensuring transparency and accountability.

Quality control and risk management

Consistency in quality control is paramount in the medical device industry. Manufacturers must ensure that each batch of products meets the required standards to avoid safety issues and reputational damage. Adhering to key standards, such as ISO 13485 for quality management systems and ISO 14971 for risk management, is essential to achieving this level of reliability and maintaining compliance in medical device manufacturing.

You may already be familiar with the Therac-25 case, which underscores the critical importance of rigorous quality control, risk management, and software safety in medical devices. Identifying and addressing risks early can save both time and resources.

How project management software helps

- Implement quality management systems: These systems can be integrated into project management tools, ensuring consistent quality checks throughout the production process.

- Automate quality control checks: Software can automatically trigger quality checks at predefined stages, ensuring that nothing is overlooked.

- Identify and mitigate risks proactively: Project management platform can highlight potential risks based on data patterns and progress tracking, enabling manufacturers to act swiftly.

Resource allocation and efficiency

Manufacturers often face resource constraints due to workforce shortages or the need to optimize limited assets. Striking a balance between production capacity and resource availability is crucial for meeting deadlines and maintaining efficiency.

How project management platform helps i

- Optimise resource allocation: Project management tools can assess the availability and skill sets of team members, ensuring the right resources are allocated to the right tasks.

- Balance workloads: Advanced software helps to prevent overloading certain team members or workstations, preventing burnout and delays.

- Identify and eliminate bottlenecks: By tracking each phase of production, the tool can identify areas where workflows are delayed, allowing for quick adjustments.

Supply chain disruptions

The global supply chain landscape has been fraught with challenges in recent years. For medical device manufacturers, supply chain disruptions can cause production delays, increase costs, and create shortages.

How project management tools help

- Improve supplier communication: Effective tools allow manufacturers to maintain constant communication with suppliers, ensuring that all parties are on the same page.

- Track inventory levels: Automated tracking of inventory in real-time helps prevent stockouts and ensures timely reordering of materials.

- Enable quick adjustments to production schedules: With real-time data, project management platforms can adjust production timelines to accommodate supply chain disruptions.

Cost management

Managing costs in medical device manufacturing, particularly in product design and development, is one of the industry’s biggest challenges. Without careful oversight, projects can easily spiral out of budget.

How project management tools help

- Track project budgets in real-time: By monitoring expenditures throughout the life cycle of a project, manufacturers can spot cost overruns early and adjust accordingly.

- Identify cost-saving opportunities: Project management tools can analyze data to identify areas where costs can be reduced, such as materials or labour.

- Streamline the product development process: With all project components integrated, manufacturers can prevent delays and reduce the overall time it takes to bring a product to market.

Team collaboration and communication

With many teams working in hybrid or remote environments, maintaining effective collaboration and communication has become more challenging. This can create delays in decision-making and hinder overall team performance.

How project management tools help

- Centralize document storage and version control: These tools ensure that all team members can access the latest versions of documents, reducing confusion and errors.

- Facilitate real-time communication: Integrated communication features, such as instant messaging or video conferencing, help team members stay in constant contact, even when working remotely.

- Enable seamless collaboration across departments: With features that integrate cross-departmental workflows, project management software promotes effective collaboration between design, production, and regulatory teams.

Technological integration

Incorporating new technologies, such as automation or AI, can be a disruptive process, especially in mid-production, and for medical device manufacturers, this challenge is further compounded by the need to strictly adhere to the FDA's guidance on cybersecurity to ensure compliance and product safety during implementation.

The challenge lies in adopting these innovations without interrupting current operations.

How project management platform with In helps

- Adapt to changing technological requirements: Agile project management tools are flexible enough to accommodate changes in technology as production needs evolve.

- Integrate with existing systems: Modern project management tools can easily integrate with other technologies, such as ERP or CRM systems, ensuring a smooth transition.

- Facilitate smoother transitions: As new technologies are adopted, project management tools can help manage the change process, train teams, and ensure that the transition is as seamless as possible.

How to achieve success in medical device manufacturing

The medical device manufacturing industry faces a range of challenges related to project and work management, from regulatory compliance to resource allocation and technological integration. However, by adopting the right project management software, manufacturers can streamline their operations, improve efficiency, and maintain a competitive edge. These solutions not only help navigate industry complexities but also enable manufacturers to meet critical deadlines, reduce costs, and deliver high-quality, compliant products to market.

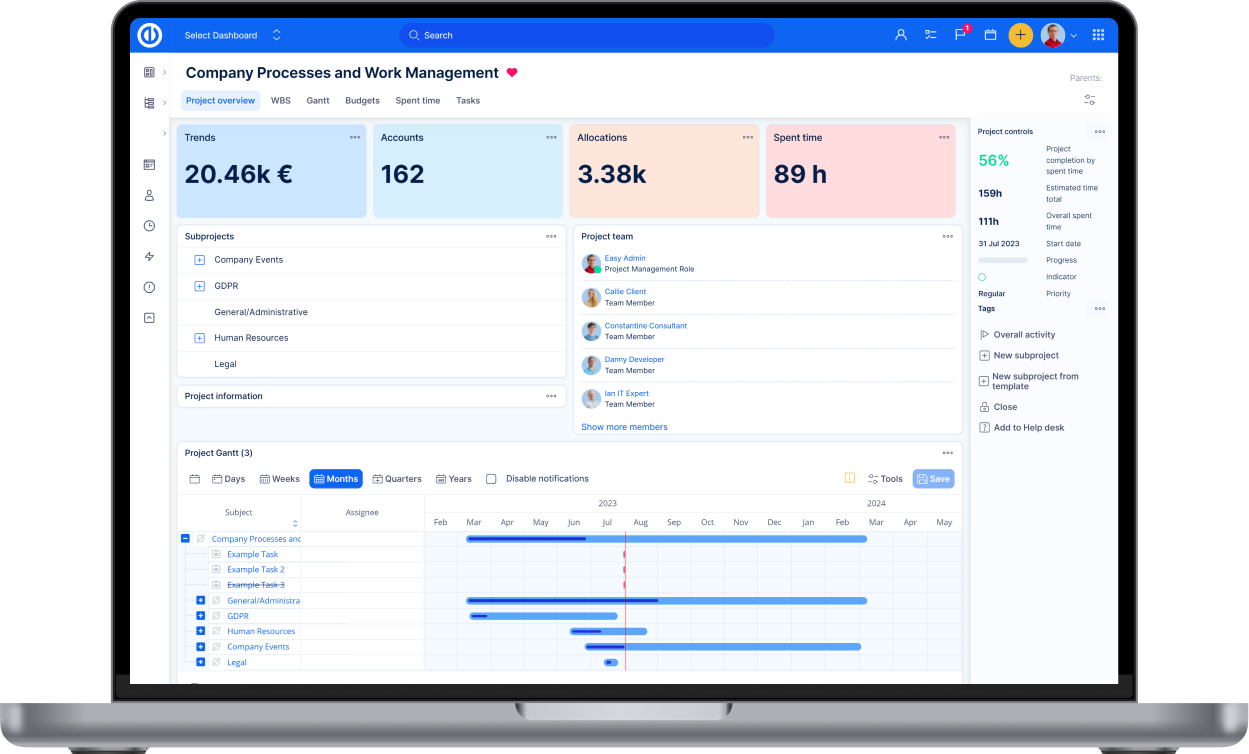

Try Easy Redmine, project management software, that integrates project planning, compliance tracking, and resource management into a single platform.