Why is Excel not suitable for manufacturing project management

Excel is still widely used in manufacturing—but 86% of professionals now see view it as a risk. As complexity grows, outdated tools hinder visibility, efficiency, and compliance—making modern project management systems no longer optional.

Would you like a version tailored more for executives or technical readers?

Table of contents

Why it’s time to move beyond spreadsheets

Professionals concerned about Excel’s role in business operations

The hidden costs of outdated tools

The case for modern project management software

Real-world impact: From lagging to leading

Why it’s time to move beyond spreadsheets

In today’s fast-paced industrial manufacturing environment, precision, efficiency, and adaptability are non-negotiable. Yet, many companies still rely heavily on tools like Excel and PowerPoint to manage complex projects. While familiar and accessible, these tools often fall short when it comes to supporting modern manufacturing demands.

To stay competitive and resilient, manufacturers must evolve—from spreadsheets to smart systems, from outdated workflows to integrated project management.

Professionals concerned about Excel’s role in business operations

Excel has been a business staple—from financial planning to project tracking, many organisations still rely heavily on spreadsheets to manage key operations. But is this reliance becoming a risk?

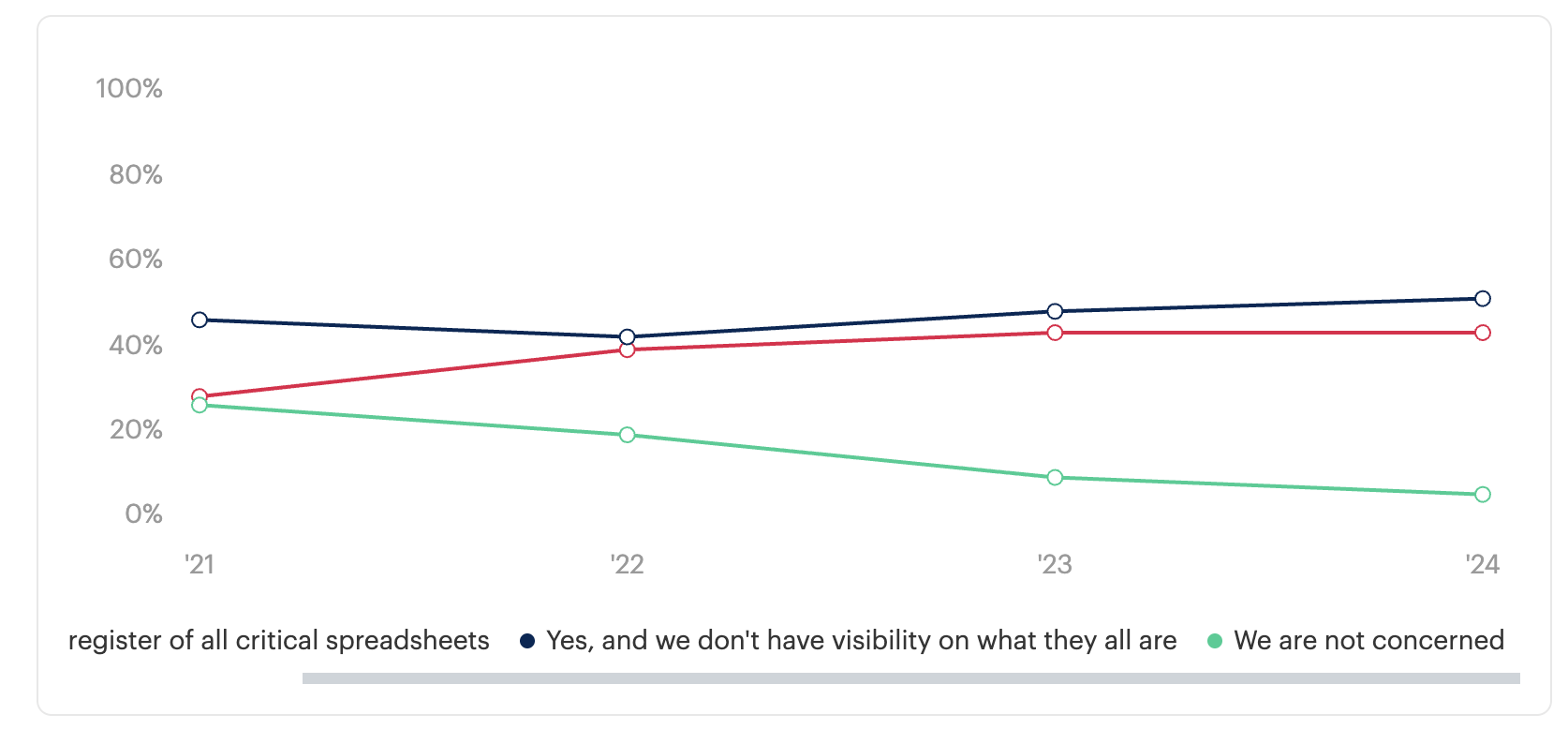

According to a recent poll conducted by the Gartner Peer Community, 306 professionals shared their view on this very topic.

The question was: Excel has been around for over 30 years and is often found to be a critical application in a business due to the volume of data managed in spreadsheets. Are you concerned with the volume of Excel spreadsheets used in your organization to manage key capabilities?

Here’s how they answered:

- 39% said Yes, and we have a register of all critical spreadsheets

- 47% said Yes, and we don't have visibility on what they all are

- 14% said We are not concerned

Gartner Peer Community poll about concerns about using Excel

Obviously, there is a trend that year over fewer and fewer companies find Excel relevant for driving complex projects.

A staggering 86% of respondents are concerned about the role Excel plays in their business processes—especially when there's limited visibility or control.

The hidden costs of outdated tools

Excel and similar tools may seem sufficient on the surface, but they create unseen risks and inefficiencies:

- Managing complexity is challenging: Spreadsheets are not designed to handle intricate workflows, interdependencies, or dynamic changes. The larger the project, the higher the risk of manual errors and version confusion.

- Lack of real-time visibility: Teams working in silos and on static files face delays, miscommunications, and missed deadlines.

- Compliance and quality oversight: Whether it's ISO, lean manufacturing, or other industry standards, maintaining audit trails and process transparency is tough without dedicated systems.

- Limited scalability: As operations grow, Excel struggles to keep up—leading to bottlenecks, duplicated efforts, and fragmented data.

What may feel like "just the way we’ve always done it" is often a drag on progress and profitability.

ISOs available with Easy Redmine

The case for modern project management software

More and more manufacturers are turning to robust project and process management platforms built specifically for complex operational environments. These solutions bring real, measurable advantages:

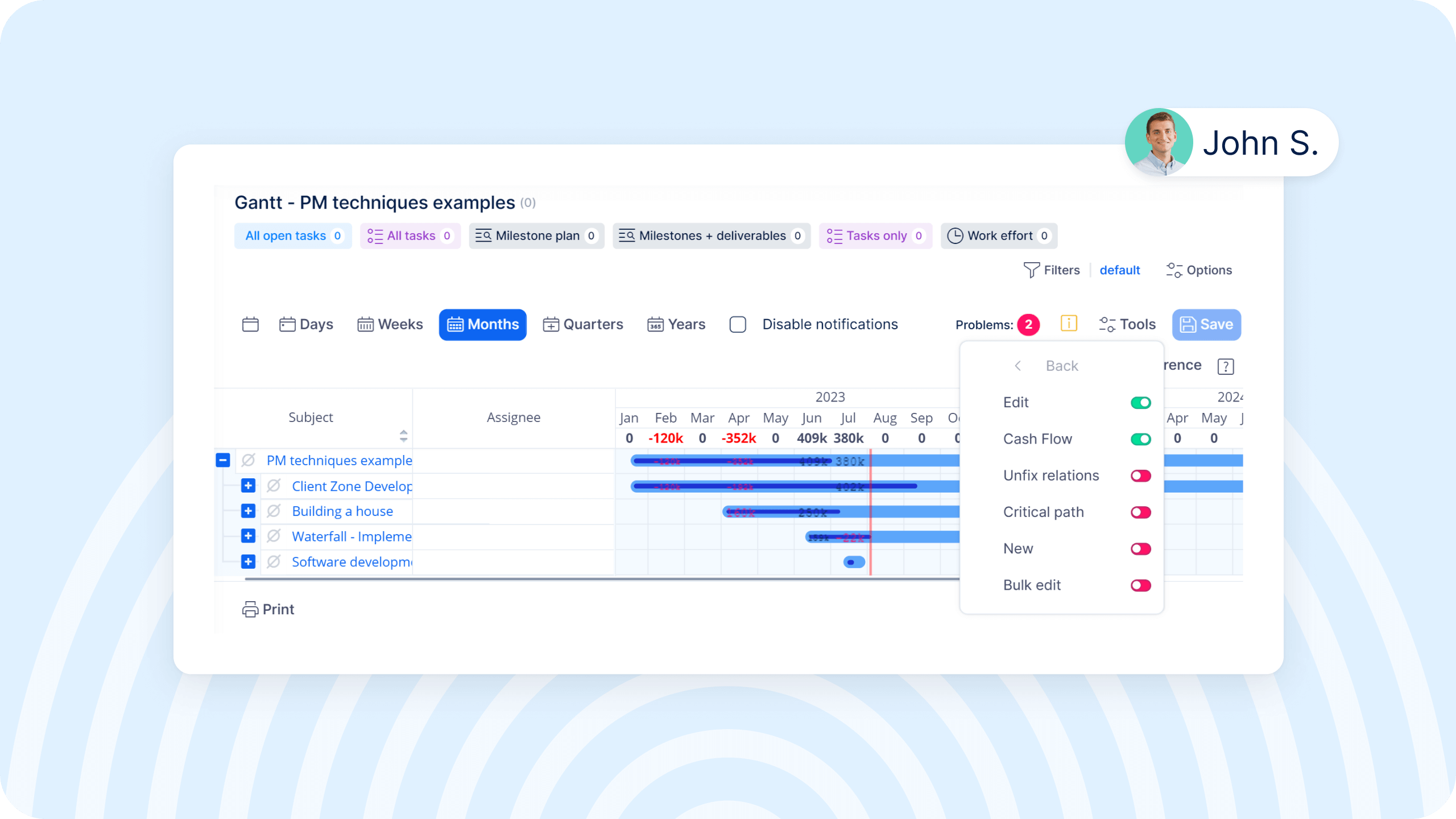

- Automated workflows: With features like Gantt charts, Kanban boards, and task templates, teams can better plan, assign, and execute work.

- Centralized collaboration: Cloud-based tools allow everyone—from engineering to operations—to stay aligned and updated in real time.

- Improved compliance and reporting: Built-in auditing, document control, and standardized reporting simplify regulatory and customer requirement tracking.

- Scalable integrations: Whether it’s ERP, CRM, inventory, or quality systems, modern platforms connect seamlessly across departments and workflows.

This shift doesn't just streamline processes—it lays the groundwork for sustainable growth and innovation.

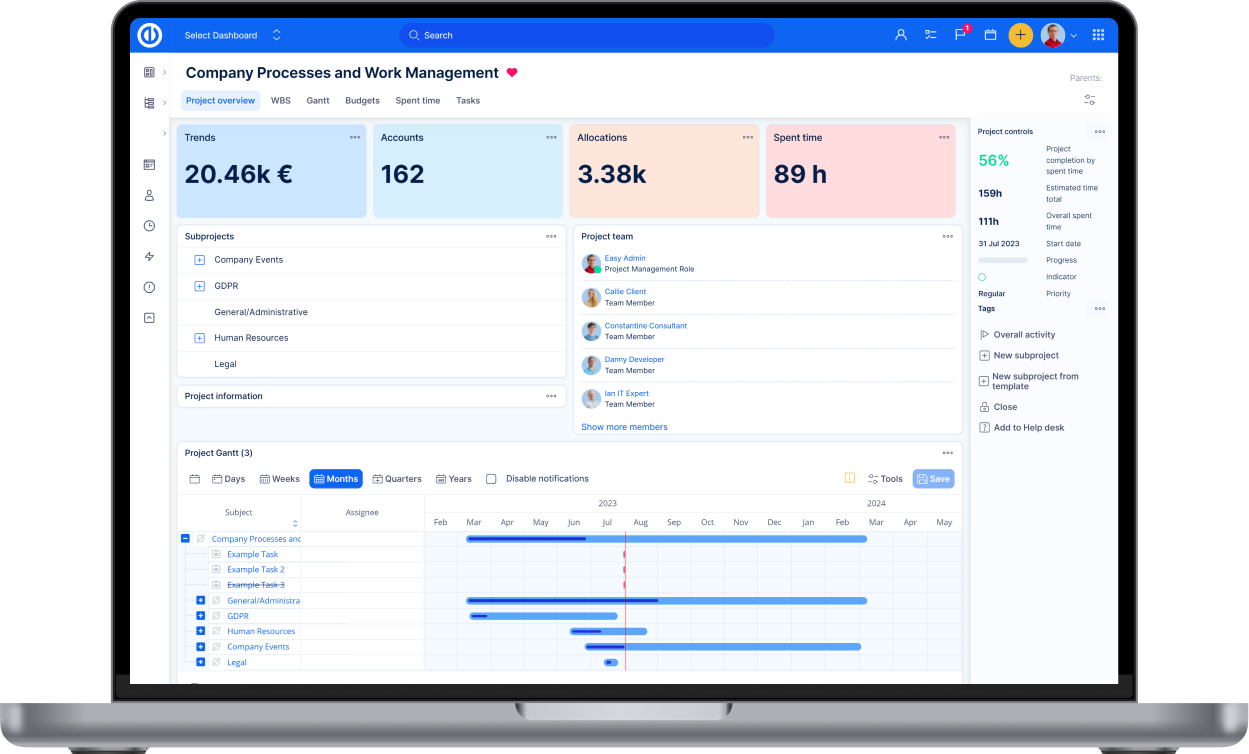

Gantt charts in Easy Redmine for supporting manufacturers

Real-world impact: From lagging to leading

Take the example of a mid-sized industrial manufacturer that replaced spreadsheet-based project tracking with a cloud-based management system. In less than six months, they achieved:

- 25% faster project completion times through clearer visibility and fewer manual updates.

- 40% reduction in missed milestones and customer escalations, thanks to automated alerts and better coordination.

- Stronger cross-functional collaboration, with reduced reliance on emails and disconnected files.

Digital transformation enabled them to boost productivity, ensure quality, and focus more time on high-value activities.

Ready to break free from Excel? Watch our "From Excel to Excellence" webinar and discover how leading manufacturers are transforming their operations.

Already decided to go towards digital transformation? Try Easy Redmine and see how it simplifies complexity, boosts productivity, and scales with your growth in manufacturing industry.