Recorded webinar: Lean methodology in manufacturing

Digital transformation is meant to simplify, not complicate. Yet too often, companies adopt new tools without first fixing the processes behind them—leading to more chaos, not less. Learn how Lean methodology can help you make smarter decisions, faster—before digitalising the mess.

Table of contents

Avoid digital chaos with Lean clarity

What is Lean methodology?

Why Lean matters in digital transformation

Lean beyond production: Top insights from the webinar

How manufacturing project management software supports Lean digital transformation

Lean thinking for real results

TL;DR

The webinar emphasizes that successful digital transformation begins not with tools but with Lean practices like 5S, Poka-yoke, and challenging habitual processes, and shows how Easy Redmine empowers manufacturing teams to apply these principles for smarter decisions, improved workflows, and real-time insights.

Avoid digital chaos with Lean clarity

As organisations work to modernise how they operate and deliver value, digital transformation is often the catalyst for change. But simply adopting new technologies doesn’t guarantee better performance.

Without structure and alignment, digital efforts can become fragmented, overcomplicated, and disconnected from real business needs. Lean methodology offers the clarity and discipline to avoid these pitfalls.

What is Lean methodology?

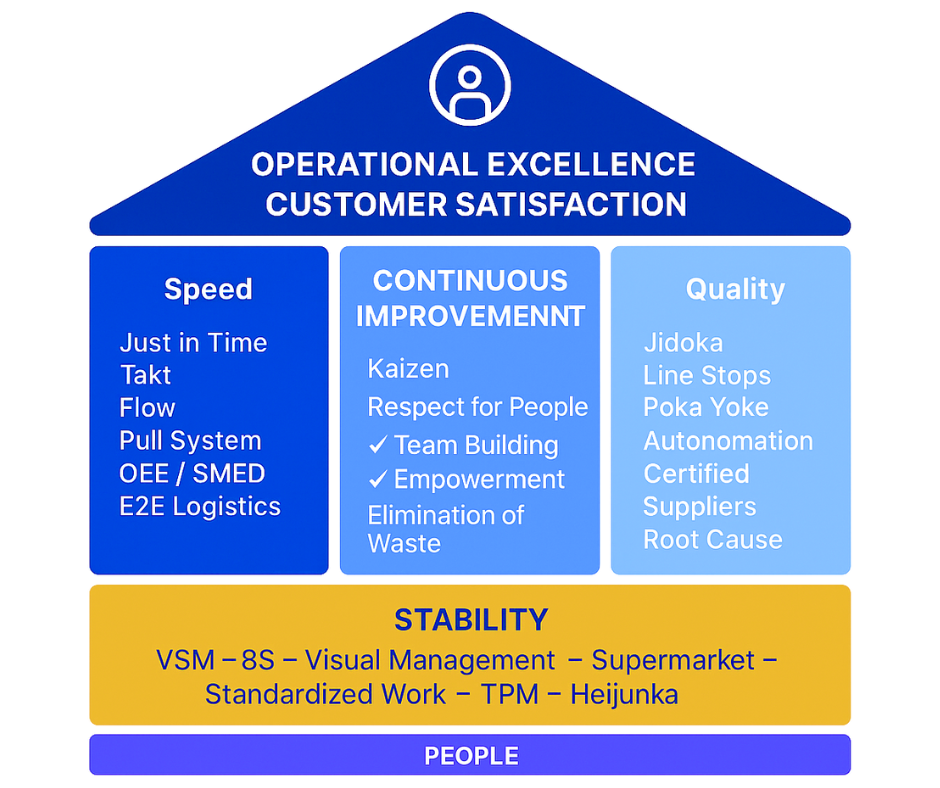

Originally developed on the shop floor in manufacturing, Lean has evolved into a universal framework for continuous improvement. It’s now widely applied across sectors—including IT, financial services, healthcare, education, logistics, and professional services.

Wherever there are workflows, teams, and customers, Lean can help eliminate waste, streamline operations, and maximise value.

Lean methodology is based on five core principles:

- Define value: Understand what truly matters to the customer.

- Map the value stream: Visualise each step in a process and remove non-value-adding activities.

- Create flow: Ensure work moves smoothly without unnecessary delays or handovers.

- Establish pull: Deliver based on actual demand rather than assumptions or forecasts.

- Pursue perfection: Continuously improve workflows through regular feedback and experimentation.

These principles are highly adaptable—whether you’re developing software, managing client accounts, onboarding new team members, or delivering services. The result? Quicker execution, clearer priorities, and more responsive teams.

Why Lean matters in digital transformation

Digital transformation isn’t just about rolling out new tools—it’s about rethinking how your organisation functions. Many businesses invest in technology without addressing underlying inefficiencies, which leads to missed opportunities and limited return on investment.

Lean methodology acts as a compass. It ensures your digital strategy is rooted in purpose, efficiency, and real customer value.

Here’s how:

- Improved efficiency: Lean helps uncover bottlenecks and redundancies in digital processes—from CRM automation to internal workflows.

- Customer-focused delivery: Every digital initiative is designed around delivering value to the end user, whether that’s a client, colleague, or stakeholder.

- Faster iteration: Lean supports agile, test-and-learn approaches—ideal for refining digital products and services.

- Engaged teams: Staff are encouraged to play an active role in improving processes, which boosts morale and accountability.

Lean beyond production: Top insights from the webinar

I recently teamed up with other expert, CI manager and manufacturing consultant Barbora Milena Matulová, to explore how Lean methodology can help you regain control over your company’s processes.

Watch the webinar recording for the full breakdown, or check out the key takeaways below if you're short on time:

- Lean is much more than just for manufacturing: It is presented as a culture, leadership style, and a way of thinking applicable across the entire company, including data analysis, reporting, information flow, and services, not solely the production floor.

- People are the core foundation of Lean: All improvements and changes should include people first, as they possess valuable knowledge and experience of processes. Empowering and involving people in the process leads to better results, smoother change acceptance, and helps them feel ownership.

- Digitalising a mess is the worst thing you can do: Before implementing digital solutions or AI, cleaning and structuring your data using Lean tools like 5S (sort, set in order, shine, standardize, sustain, plus safety, systematic, cycleization) is essential.

- The biggest waste nowadays is the waste of human potential: Having people spend time on manual tasks like downloading data, making Excel tables, and creating charts is a significant waste that software and AI could handle in real-time.

- Continuous improvement comes from challenging the status quo: Asking "why" you do something is a simple but powerful way to identify activities done purely out of habit that may have no value and can potentially be eliminated.

- Quality should be built into the process: The principle "quality is made, not controlled" means focusing on error-proofing (Poka-yoke) to make processes so robust they prevent mistakes from happening, rather than relying on checks afterwards.

How manufacturing project management software supports Lean digital transformation

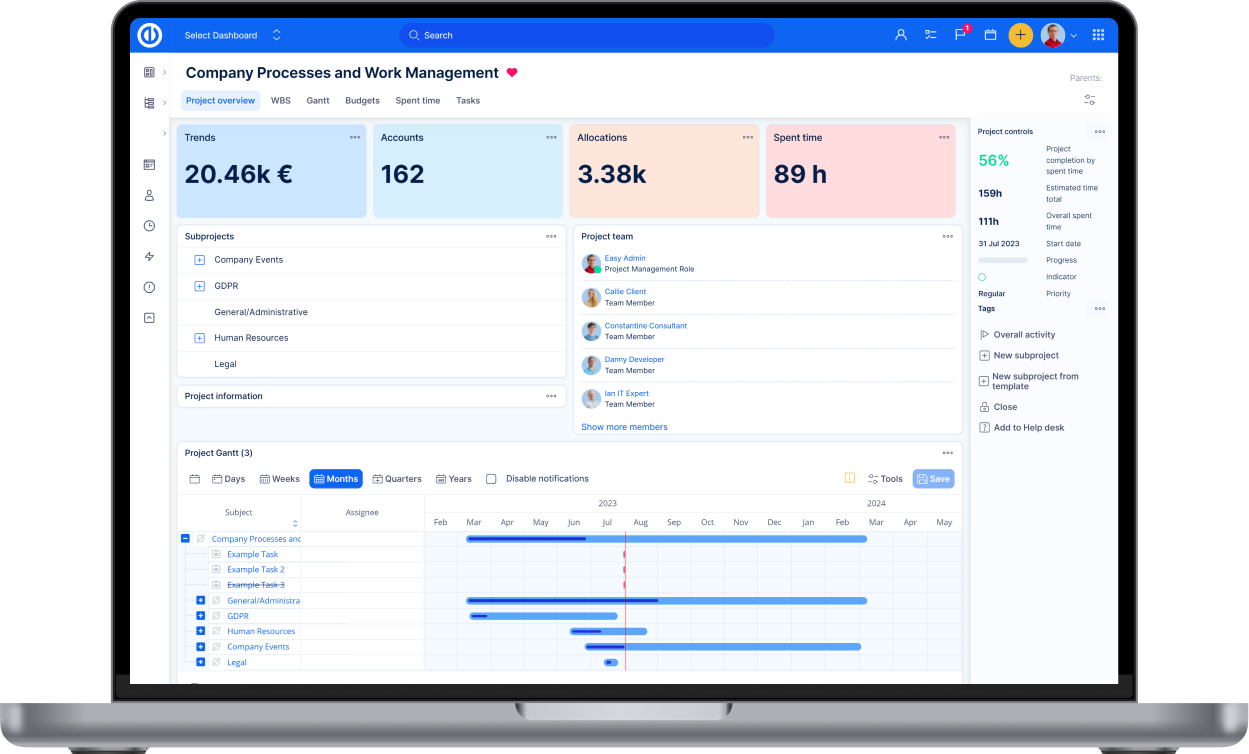

Easy Redmine, as powerful project and process management solution, supports the application of Lean principles across your organisation—whether you’re leading IT transformation, process improvement, or operational change.

Key features of Easy Redmine include:

- Visual workflow tools: Use Kanban boards and value stream mapping to visualise work, identify inefficiencies, and improve delivery flow.

- Real-time collaboration: Keep teams aligned with centralised communication and live task tracking.

- Performance insights: Built-in dashboards and reports help teams make data-informed improvements.

- Resource management and time management: Allocate team capacity wisely and measure progress clearly.

From optimising internal operations to streamlining project delivery, Easy Redmine enables teams to apply Lean thinking across all areas of digital transformation.

Lean thinking for real results

The modern workplace demands more than technology alone—it requires leaner processes, agile systems, and sharper focus. Easy Redmine gives you the tools to turn Lean thinking into real-world results.

Try Easy Redmine for free and take the first step towards a more efficient, digitally-enabled organisation.