ITSM tools in manufacturing: The secret to reducing downtime and costs

In modern manufacturing, even a minor IT hiccup can grind production to a costly halt. Discover how ITSM turns these challenges into opportunities for efficiency, cost savings, and uninterrupted operations.

Table of contents

The role of ITSM in manufacturing

ITMS benefits

ITSM prevents unplanned downtime losses

Lower costs, faster fixes

Reducing downtime and costs with smart ITSM practices

ITSM solution: Easy Redmine

TL;DR

IT Service Management by Easy Redmine helps manufacturers minimise downtime, control costs, and improve efficiency by streamlining IT issue resolution, fostering collaboration, and leveraging automation and AI to keep production running smoothly.

The role of ITSM in manufacturing

Technology is the backbone of modern manufacturing, from automated machines on the shop floor to logistics software managing supply chains. IT systems are essential to keeping production running efficiently. However, when IT problems arise, they can slow down production or even bring it to a halt. This leads to lost time, increased costs, and missed deadlines.

IT Service Management provides a structured way to handle IT-related issues, ensuring that problems are resolved quickly and effectively.

ITSM is a set of processes that help businesses manage IT services in an organized way by improving response times, reducing downtime, and keeping operations running without unnecessary disruptions.

ITMS benefits

- Minimised downtime: IT Service Management helps prevent and manage IT failures, keeping production on track.

- Improved collaboration: A centralised service management tool ensures IT and production teams work together efficiently.

- Cost control: ITSM reduces unnecessary IT expenses through automation, predictive maintenance, and efficient resource allocation.

- Smarter decision-making: With better asset management and AI-powered automation, manufacturers gain greater control over IT operations.

ITSM prevents unplanned downtime losses

Unplanned downtime is a major challenge in manufacturing. When a production system fails, every minute of inactivity results in lost revenue and delayed orders. According to Siemens, the cost of an hour of unplanned downtime can range from an average of $39,000 for factories producing FMCG to over $2 million in the automotive industry.

ITSM helps reduce this risk by:

- ensuring that IT teams follow clear procedures for incident management, defining responsibilities and timelines for each step,

- preventing recurring problems by identifying root causes of past issues and applying predictive methods to avoid future disruptions,

- enabling controlled change management, ensuring that any modifications to systems or processes are carefully planned, tested, and implemented.

As a result, IT disruptions have less impact on production, allowing manufacturing companies to meet their targets and maintain customer satisfaction.

In many factories, IT and production teams work separately, which can lead to delays in problem-solving. A unified service management tool improves communication, allowing IT and operations teams to collaborate efficiently and resolve issues faster. This not only speeds up problem resolution but also helps prevent future disruptions.

Lower costs, faster fixes

Manufacturing companies also face pressure to control costs, and ITSM plays a key role in improving the efficiency of IT support and maintenance. By using structured processes and automation, businesses can reduce the time spent fixing IT problems, optimise resource allocation, and avoid expensive last-minute repairs.

In fact, companies that implement ITSM frameworks have reported a nearly 23% reduction in average resolution time due to automated business processes, allowing IT teams to address issues more swiftly and effectively. Over time, this leads to lower operational costs and a more predictable budget for IT services.

Reducing downtime and costs with smart ITSM practices

To keep production running efficiently, manufacturers must focus on two key goals: minimising downtime and controlling IT costs. ITSM provides several strategies to achieve this.

- Proactive incident management: Instead of waiting for problems to occur, ITSM encourages manufacturers to identify and resolve issues early. By integrating monitoring systems that log alerts, IT teams can address potential failures before they impact production.

- Effective change management: Making changes to IT systems, such as software updates or new equipment installations, can be risky. A structured ITSM approach ensures all changes are planned, tested, and implemented with minimal disruption to production—reducing unexpected costs and downtime.

- Asset and configuration management: Keeping track of IT assets, such as servers and network equipment, helps manufacturers maintain control over their technology. With clear asset tracking, troubleshooting becomes easier, unplanned expenses are reduced, and IT teams can avoid over-purchasing or unexpected licensing costs.

- Knowledge management: A well-maintained Knowledge Base stores solutions to common IT issues, allowing teams to resolve problems quickly and consistently. Not only does this minimise disruptions, but it also reduces reliance on IT support staff—optimising labour costs. AI-powered ITSM solutions further enhance this by providing instant, data-backed responses.

- Automation and AI support: Automating repetitive IT tasks, such as system monitoring and software updates, reduces the risk of human error. AI assistants help with incident evaluation and suggest solutions, saving valuable time. With an on-premises AI ITSM tool, companies can securely manage their internal knowledge while keeping sensitive data protected.

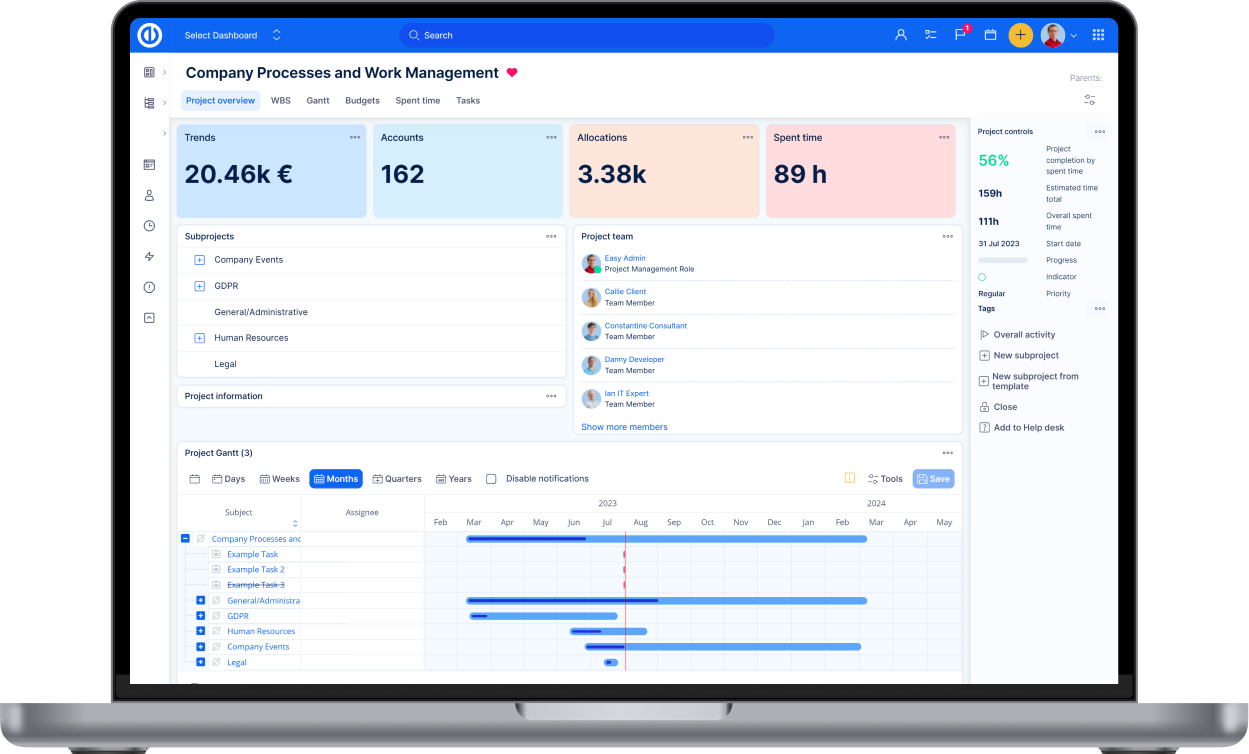

HelpDesk dashboard in Easy Redmine software

ITSM solution: Easy Redmine

Easy Redmine ITSM supports all these mentioned principles with dedicated tools for incident management, change tracking, asset monitoring, knowledge sharing, and AI-powered enhancements—helping manufacturers improve efficiency and reduce downtime.

Still hesitating? See how ITSM software tailored for manufacturing helps you run smoother operations, reduce risk, and save money and download the case study!

Try Easy Redmine with ITSM module for free and reduce downtime, cut costs, and solve IT issues faster than ever—backed by automation, AI, and practical tools for manufacturers.